Gate valve special machine is a kind of mechanical equipment specially used for gate valve production and processing, it can efficiently and accurately complete the key processes in the gate valve manufacturing process, the following from the functional characteristics, application scenarios, advantages and other aspects for you to introduce in detail:

- Functional characteristicsMulti-process integration: the gate valve special machine usually integrates a variety of processing functions, which can complete the turning, milling, drilling, boring, tapping and other key components of the gate valve spool, seat, valve body and other processing processes. Through one clamping, multiple parts can be processed on the same equipment, effectively ensuring the dimensional accuracy and position accuracy of each processing part.

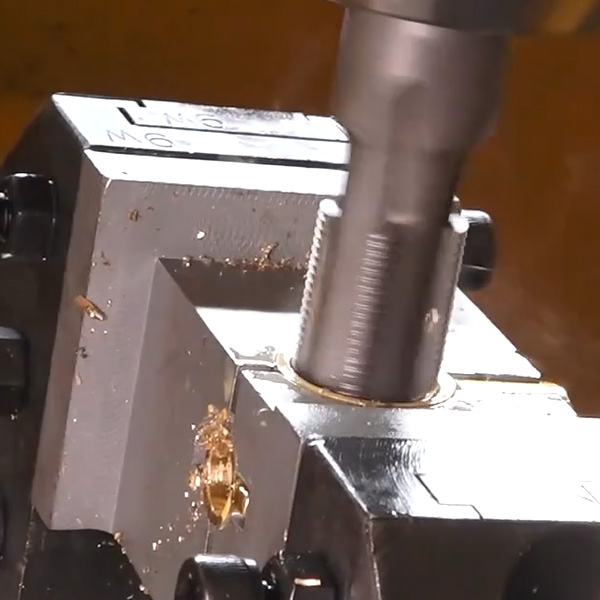

High-precision machining: Equipped with high-precision transmission system and positioning device, can achieve accurate motion control, high processing accuracy, can ensure the sealing performance of the gate valve and the overall quality. For example, when machining the sealing surface of the valve seat, high flatness and surface roughness requirements can be achieved to ensure the tightness of the gate valve when closed.

High degree of automation: The use of advanced numerical control system and automatic control technology, can realize the automation of the processing process. The operator only needs to install the workpiece and input the corresponding processing program, and the equipment can automatically complete the processing task according to the preset parameters, reducing manual intervention and improving the stability of production efficiency and processing quality.

Tool management system: with automatic tool replacement and management functions, can automatically select and replace the tool according to different processing procedures, reduce the tool replacement time, improve the utilization rate of the equipment. At the same time, the tool management system can also monitor and manage the service life of the tool, and remind the operator to replace the tool in time to ensure the processing quality. - Application scenarioGate valve manufacturers: widely used in all kinds of gate valve manufacturers, for mass production of different specifications and models of gate valves. Whether it is a small civil gate valve or a large industrial gate valve, the gate valve special machine can play its efficient and accurate processing advantages to meet the production needs of enterprises.

Valve maintenance enterprises: In the field of valve maintenance, gate valve special machine also has an important application. It can repair and process the damaged gate valve, such as reprocessing the worn spool and seat, restoring its original size and accuracy, and extending the service life of the gate valve. - advantageImprove production efficiency: multi-process integration and automatic processing, greatly reduce the number of workpiece handling and clamping between different equipment, shorten the processing cycle, improve production efficiency. Compared with the traditional processing methods, the gate valve special machine can complete more processing tasks in a shorter time to meet the large market demand for gate valve products.

Ensure processing quality: high-precision processing and stable automatic control to ensure the consistency of gate valve processing quality. The dimensional accuracy, shape and position tolerance and surface quality of the product can be effectively guaranteed, thus improving the performance and reliability of the gate valve, and reducing the cost of product scrapping and after-sales maintenance caused by processing quality problems.

Reduce labor intensity: the degree of automation is high, the operator only needs to carry out work such as workpiece clamping, program input and equipment monitoring, reducing the time and intensity of manual direct participation in processing, improving the working environment and reducing labor costs. At the same time, it also reduces the processing error caused by human factors and improves the stability of processing quality.