Daily maintenance

- Pre-shift maintenanceCheck whether the handle and button of each part of the lathe are in the correct position, and whether there is enough lubricating oil in each lubricating part.

Wipe the surface of the lathe, remove dust, oil and chips and other debris, keep the lathe appearance clean.

Start the lathe and run empty for 3-5 minutes to check whether all parts of the lathe are running normally and whether there are abnormal sounds and vibrations.

In-shift maintenancePay attention to observe the operation of the lathe, including the spindle speed, feed speed, cutting force, etc., if there is an anomaly, it should be stopped in time for inspection.

Clean the cuttings and debris on the lathe workbench in time to prevent the cuttings from scratching the workbench and entering the lathe interior.

Check the lubrication system of the lathe regularly to ensure that each lubrication point is well lubricated, and if there is oil leakage, it should be dealt with in time.

After-work maintenanceTurn off the power supply and turn off the lathe power switch to ensure safety.

Thoroughly clean the cuttings, oil and debris inside and outside the lathe, wipe the lathe completely, and keep the lathe clean.

The parts of the lathe will be returned to the position, the tools, fixtures, etc., to keep the work site orderly.

Regular maintenance

- Weekly maintenanceCheck the tightness of the lathe’s drive belt, and adjust or replace it in time if it is loose.

Clean the electrical box of the lathe, remove the internal dust and debris, check whether the connection of the electrical components is firm, whether there is loosening, burning and other phenomena.

Check the cooling system of the lathe, clean the cooling water tank, replace the coolant to ensure that the coolant is clean and sufficient, and the cooling system works normally.

Monthly maintenanceThe guide rail, screw, nut and other parts of the lathe are cleaned and lubricated, and the appropriate amount of lubricating oil or grease is applied to reduce wear and ensure the flexible operation of moving parts.

Check the oil quality and oil quantity of the headstock and feed box of the lathe. If the oil quality deteriorates or the oil quantity is insufficient, the lubricating oil should be replaced or added in time.

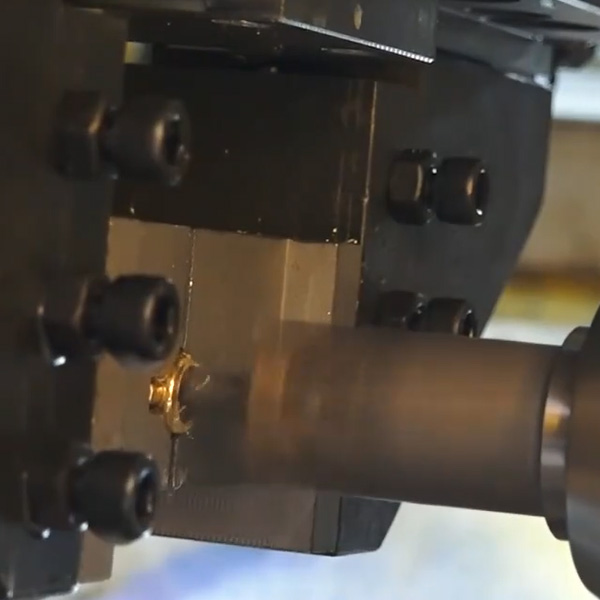

Check the tool clamping device of the lathe to ensure that the tool is firmly installed and the clamping force is uniform to prevent the tool from loosening during the cutting process.

Quarterly maintenanceCheck and adjust the accuracy of the lathe, such as the radial runout of the main shaft, the axial movement, the flatness and perpendicularity of the table, etc., if the accuracy is out of whack, it should be adjusted or maintained in time.

Check the hydraulic system of the lathe, clean the hydraulic oil tank and filter, replace the hydraulic oil, check the working condition of the hydraulic pump, hydraulic cylinder and other components, to ensure the stable operation of the hydraulic system and no leakage.

Check and maintain the protective device of the lathe, such as protective cover, protective door, etc., to ensure that it is safe and reliable, and can effectively protect the safety of the operator.

Annual maintenanceCarry out a comprehensive disassembly inspection of the lathe, clean the parts, check the wear condition, and replace the parts with serious wear.

Carry out a comprehensive inspection and maintenance of the electrical system of the lathe, replace the aging wires, cables and electrical components, and debug the electrical control system to ensure its stable and reliable performance.

Paint or paint the appearance of the lathe to prevent rust and keep the lathe beautiful.