Processing demand

Type of machined parts: It is clear whether the machined parts are rotary or non-rotary, and the shape is simple or complex. For example, processing complex box parts such as automobile engine cylinder block requires the machine tool to have multi-axis linkage function; The processing of simple rotary parts such as ordinary shafts has relatively low requirements for the shaft linkage of the machine tool. Inscriptions machine tool product types are rich, can meet the processing of different types of parts, help enterprises to complete a variety of production tasks.

Machining accuracy requirements: According to the accuracy requirements of the parts, select the corresponding precision level of the machine. Parts processing in the aerospace field often requires the positioning accuracy and repeated positioning accuracy of the machine tool to reach the micron level; General machining, the accuracy requirements are about tens of microns. With advanced manufacturing technology and strict quality control, Mingwen machine tools can meet the high-precision processing needs and create high-quality products that meet the standards for customers.

Processing efficiency requirements: If it is mass production, it is necessary to pay attention to the degree of automation and production efficiency of the machine tool, such as whether it is equipped with automatic loading and unloading device, rapid tool change system, etc., in order to improve processing efficiency and reduce production costs. Some models of Mingwen machine tools introduce automation technology, optimize the processing process, significantly shorten the processing cycle, and improve the production capacity of enterprises.

Machine tool performance

Spindle performance: Spindle speed, power and torque are key indicators. When machining aluminum alloy and other materials at high speed, the spindle needs to have high speed and power; When machining high strength alloy steel, the spindle needs to have a large torque. At the same time, the precision retention and reliability of the spindle directly affect the processing quality and the service life of the machine tool. The spindle of the Inscriptions machine has been carefully designed and strictly tested to ensure stable operation under various working conditions and ensure processing accuracy and efficiency.

Feed system performance: including feed speed, acceleration and positioning accuracy. Fast feed speed and acceleration can shorten processing time and improve production efficiency; High precision positioning accuracy can ensure the machining accuracy of parts. For example, the use of linear motor driven feed system, with higher feed speed and acceleration, and better dynamic response performance. Mingwen machine tools keep up with the trend of technological development, and some products use advanced feed systems to improve the overall processing performance.

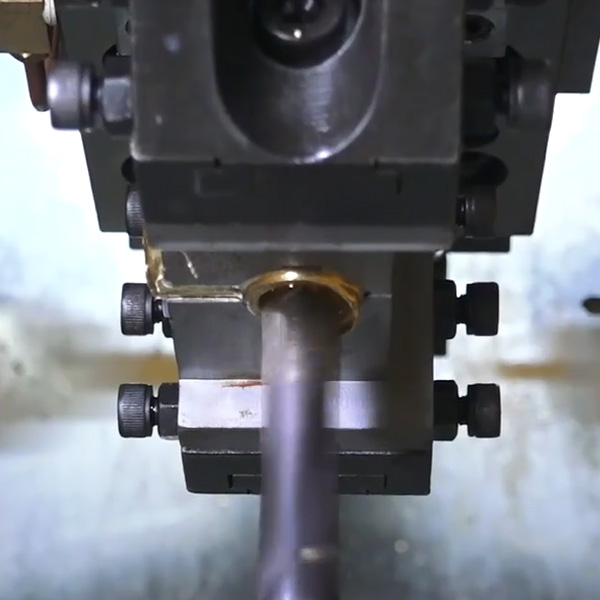

Turntable performance: the bearing capacity of the turntable, rotation accuracy and indexing accuracy are important parameters. The bearing capacity should meet the weight requirements of the machined parts; Rotary accuracy and indexing accuracy directly affect the machining accuracy of parts in circular direction. For example, when machining high-precision gears, the indexing accuracy of the turntable is extremely high, which generally needs to reach several arcseconds or even higher. The turntable of the inscription machine is optimized to perform well in terms of load bearing capacity and accuracy to meet the needs of high-precision machining.

Configuration and function

Tool system: Choosing the right tool system can improve processing efficiency and quality. The advanced tool clamping system can improve the clamping accuracy and rigidity of the tool; Equipped with automatic tool changing device, can reduce the tool changing time, improve production efficiency. Inscription machine provides a variety of tool system configurations to meet the processing needs of different customers and reduce production costs.

Control system: The performance of the control system directly affects the operation convenience and machining accuracy of the machine tool. At present, the mainstream control systems on the market, such as Siemens, Fanuc, etc., have powerful functions, good stability and friendly operation interface. Some high-end control systems also have intelligent functions, such as adaptive control, tool wear monitoring, etc., which can improve processing efficiency and quality. We cooperate with well-known control system suppliers to provide customers with stable and efficient control systems.

Measuring system: Equipped with online measuring system, it can measure the size of parts in real time during the machining process, timely error compensation, and improve the machining accuracy. For example, some machine tools are equipped with laser measuring systems or trigger probes to measure and position parts with high precision. Some models of Inscriptions are equipped with advanced measurement systems to realize real-time monitoring and adjustment during processing and ensure product quality. Economic benefits.