Rotary multi-axis composite special aircraft can be classified according to different classification standards, the following are some common classification methods and specific classification:

- Sorted by number of axesThree-axis turntable compound special machine: usually has three motion axes, generally X, Y, Z axis, can achieve motion control in three-dimensional space, can complete some relatively simple processing tasks, such as surface milling, drilling, etc.

Four-axis turntable compound special aircraft: on the basis of three axes, A rotating axis is added, usually A or B axis. The A axis rotates around the X axis and the B axis rotates around the Y axis. The four-axis special machine can process the plane or surface with a certain Angle requirement, and can realize more complex processing technology, such as drilling and milling on the inclined plane.

Five-axis turntable compound special machine: The five-axis turntable compound special machine adds A rotating axis on the basis of four axes to form five axes of motion, and the common combinations are X, Y, Z, A, C axis or X, Y, Z, B, C axis. The C axis is rotated about the Z axis. The five-axis special machine can carry out high-precision machining of complex surfaces, and can realize any Angle and position adjustment of the tool in space. It is widely used in aerospace, auto parts, mold manufacturing and other fields, and is used for processing impeller, blade, complex cavity and other parts. - Classified by processing technologyMilling turntable multi-axis composite special machine: mainly milling processing, the workpiece can be plane milling, profile milling, cavity milling and other milling processes. Through multi-axis linkage, various complex shapes of planes and surfaces can be machined.

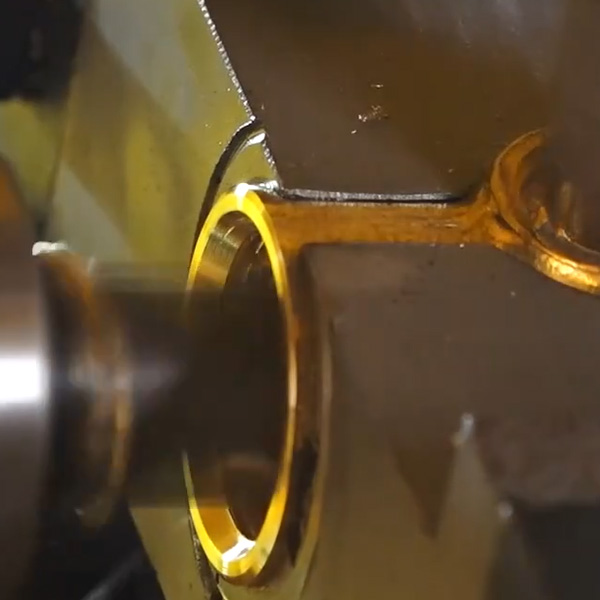

Turning turntable multi-axis composite special machine: focusing on turning processing, can complete the outer circle, inner hole, end face, thread and other turning processes. Multi-axis linkage can realize the complex shape processing of rotary parts, such as milling or drilling at the same time of turning, to improve the processing accuracy and efficiency of parts.

Drilling turntable multi-axis composite special machine: with drilling processing as the main process, it can carry out multiple drilling operations at different positions and angles on the workpiece. The multi-axis linkage ensures the position accuracy and Angle accuracy of the drilling, which is suitable for parts processing requiring a large number of drilling, such as circuit boards, porous molds, etc.

Grinding turntable multi-axis composite special machine: used for grinding the workpiece surface to obtain high surface finish and dimensional accuracy. Through multi-axis linkage, it can realize the grinding of complex shape surfaces, such as camshaft, crankshaft and other parts.

Comprehensive processing turntable multi-axis composite machine: This kind of machine integrates a variety of processing processes, such as milling, turning, drilling, grinding, etc., can complete multiple processes on a machine tool, to achieve one-stop processing of complex parts, reduce the workpiece between different machine tools clamping and transfer, improve processing efficiency and accuracy, reduce production costs. - Classified by turntable structureSingle turntable multi-axis composite special machine: there is only one turntable, the workpiece is installed on the turntable, and the processing is realized through the rotation of the turntable and the linkage of the multi-axis. This structure is suitable for processing parts with relatively simple shape and small size, and has the advantages of compact structure and small footprint.

Double turntable multi-axis special machine: with two turntables, it is usually possible to achieve fast clamping and switching of the workpiece, improving the processing efficiency. For example, when one turntable is processing, another turntable can load and unload the workpiece or reserve the position, which reduces the auxiliary time of the machine tool and is suitable for mass production.

Multi-station turntable multi-axis composite special machine: there are multiple stations on the turntable, each station can be installed with different fixtures or tools, through the rotation of the turntable to achieve the switch between different stations, so as to complete a variety of different processing tasks. This structure is suitable for the multi-process processing of complex parts, and can complete the processing of multiple parts in a single clamping, improving the processing accuracy and production efficiency.