In the field of industrial processing, the rational use of the turntable machine produced by the inscription machine plays a key role in improving processing efficiency and ensuring product quality. The following details the precautions for using the inscriptions machine tool turntable machine for you.

Before work: careful inspection is necessary

Every time before the use of the inscriptions machine turntable machine, to carry out a comprehensive inspection of the equipment. Check the appearance and ensure that the components are securely connected to prevent running faults due to loosening. The transmission part is the focus of inspection, and it is necessary to confirm that the belt tension is moderate, and the chain is not disconnected and locked. Lubrication and cooling system is equally important, in the guide rail, screw and other key lubrication points to add suitable lubricating oil, maintain the lubrication state of the equipment, reduce wear. Ensure that the coolant of the cooling system is sufficient and clean to avoid impurities affecting the processing accuracy. Finally, professional measuring tools are used to calibrate the positioning accuracy of the turntable, laying an accurate foundation for subsequent processing.

Before work: careful inspection is necessary

Every time before the use of the inscriptions machine turntable machine, to carry out a comprehensive inspection of the equipment. Check the appearance and ensure that the components are securely connected to prevent running faults due to loosening. The transmission part is the focus of inspection, and it is necessary to confirm that the belt tension is moderate, and the chain is not disconnected and locked. Lubrication and cooling system is equally important, in the guide rail, screw and other key lubrication points to add suitable lubricating oil, maintain the lubrication state of the equipment, reduce wear. Ensure that the coolant of the cooling system is sufficient and clean to avoid impurities affecting the processing accuracy. Finally, professional measuring tools are used to calibrate the positioning accuracy of the turntable, laying an accurate foundation for subsequent processing.

Running time: real-time monitoring to ensure stability

During the operation of the rotary machine, the operator should always pay attention to the status of the equipment. Pay close attention to the spindle speed, feed speed and other parameters, once the speed fluctuation, feed lag and other abnormalities, must immediately stop troubleshooting. Tool cutting sound is the “barometer” of equipment operation, if the sound is abnormal, it may be the tool wear or workpiece clamping instability, need to be handled in time to prevent affecting the processing accuracy, resulting in damage to the tool and workpiece. At the same time, pay attention to the rotation of the turntable, if the turntable vibration, may cause processing deviation, at this time to check the support structure of the turntable and transmission components. In addition, timely cleaning of chips to prevent accumulation hindering the operation of equipment and affecting the processing process.

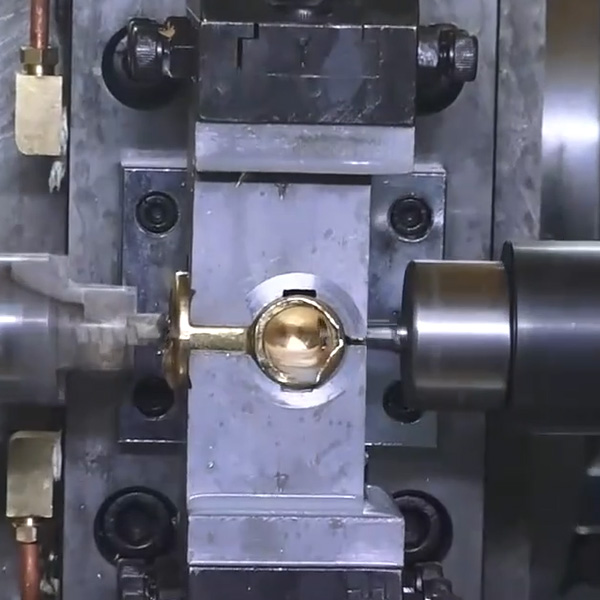

Clamping link: equal emphasis on adaptation and stability

The clamping of the tool and the workpiece is directly related to the processing quality. According to the processing materials and process requirements, select suitable tools, such as hard materials can be selected carbide tools. When installing the tool, ensure that it is closely fitted with the tool holder and firmly installed to avoid loosening and throwing out, causing safety accidents. Workpiece clamping can not be ignored, according to the shape and size of the workpiece, select the appropriate fixture to ensure that the clamping is stable and the position is accurate, and prevent the workpiece displacement during processing, affecting the processing effect.

During the operation of the rotary machine, the operator should always pay attention to the status of the equipment. Pay close attention to the spindle speed, feed speed and other parameters, once the speed fluctuation, feed lag and other abnormalities, must immediately stop troubleshooting. Tool cutting sound is the “barometer” of equipment operation, if the sound is abnormal, it may be the tool wear or workpiece clamping instability, need to be handled in time to prevent affecting the processing accuracy, resulting in damage to the tool and workpiece. At the same time, pay attention to the rotation of the turntable, if the turntable vibration, may cause processing deviation, at this time to check the support structure of the turntable and transmission components. In addition, timely cleaning of chips to prevent accumulation hindering the operation of equipment and affecting the processing process.

Clamping link: equal emphasis on adaptation and stability

The clamping of the tool and the workpiece is directly related to the processing quality. According to the processing materials and process requirements, select suitable tools, such as hard materials can be selected carbide tools. When installing the tool, ensure that it is closely fitted with the tool holder and firmly installed to avoid loosening and throwing out, causing safety accidents. Workpiece clamping can not be ignored, according to the shape and size of the workpiece, select the appropriate fixture to ensure that the clamping is stable and the position is accurate, and prevent the workpiece displacement during processing, affecting the processing effect.

Whole process: strictly observe the safety bottom line

Safety is the primary criterion for using inscriptions machine turntables. Operators must wear work clothes, safety hats, protective gloves and other equipment, do not wear loose clothing or jewelry, to prevent involvement in moving parts. When the equipment is running, do not approach the moving area to avoid accidents. Keep work area clean and tidy, remove debris in time. Regular inspection of safety protection devices, such as protective doors, emergency brake buttons, etc., to ensure rapid response in emergency situations, to ensure the safety of personnel and equipment.

Safety is the primary criterion for using inscriptions machine turntables. Operators must wear work clothes, safety hats, protective gloves and other equipment, do not wear loose clothing or jewelry, to prevent involvement in moving parts. When the equipment is running, do not approach the moving area to avoid accidents. Keep work area clean and tidy, remove debris in time. Regular inspection of safety protection devices, such as protective doors, emergency brake buttons, etc., to ensure rapid response in emergency situations, to ensure the safety of personnel and equipment.